High temperatures and dangerous atmospheres call for a reliable source of ventilation in any industry. Industrial Fans High Temperature For petrochemical plants, power stations, and manufacturing facilities. Column ventilators (explosion-proof), Panel fans, and Circular duct recuperators are designed to regulate security, comfort, and high-performance equipment. These are a solid solution for handling heat and volatile atmospheres, which have the potential for explosions, overheating, and equipment failure. In this piece, we will discuss the construction, uses, and benefits of explosion-proof tube axial fans as a crucial component in the safety and operational process.

The Importance of Industrial Fans in High-Temperature Environments

There is widespread use in industrial facilities operated at high temperatures with explosive atmospheres and intense heat, such as power generation plants, refineries, and chemical plants. Failure to adequately ventilate in such scenarios can lead to operational issues, unsafe work environments, or disastrous explosions.

This is where explosion-proof tube axial fans can be very useful. They minimize the threat of dangerous fume buildup, heat buildup , and potentially catastrophic pressure. These fans are designed so sparks or heat cannot be produced, which might ignite flammable vapors in hazardous locations.

Explosion-Proof Tube Axial Fans Design And Application

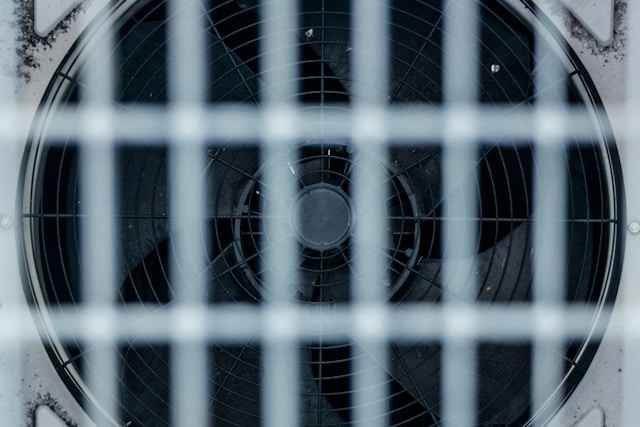

Tube Axial Fans – Explosion Proof are built for the toughest applications. These are axial flow fans, in which air movement is parallel to the axial direction of the fan. This is especially preferred for systems that need aggressive cooling or ventilation, like that provided for such large-scale industrial machinery.

Their safety is ensured by the fact that the fan is both explosion-proof. These fans are in shipping container enclosures that prevent combustion in explosive atmospheres, such as from sparks or heat buildup. Various materials, including steel and cast aluminum, are used in constructing them, making them sturdy to resist high temperatures and physical impacts.

The motors are installed inside explosion-proof casings so that no spark from an electrical malfunction could set the area on fire. This makes them perfect for hazardous material handling facilities, including both flammable gases and volatile chemicals.

Uses and Applications of Explosion-Proof Tube Axial Fans

These specialized fans are found in a few high-risk units where safety is paramount. The following are a few of the key industries that depend on explosion-proof tube axial fans:

Petrochemical and Chemical Plants

In petrochemical and chemical manufacturing facilities, where flammable gases and hazardous chemicals are used, safety is an important element. Explosion-proof tube Axial Fans are vital for ventilating a hazardous gas environment while preventing the buildup of toxic gases to avoid an explosive atmosphere. The fans help control temperature and humidity, thus ensuring safe working conditions and preventing equipment from overheating.

Power Plants

Power plants, particularly those that burn fossil fuels, often experience high operational temperatures. These environments require explosion proof tube axial fans to cool turbines, boilers, and other heat-sensitive equipment. The ability of these fans to manage air quality and temperature ensures that plant operations run smoothly while minimizing the risk of ignition in the presence of combustible gases.

Manufacturing and Metal Processing

Machinery in metalworking industries like casting, forging, and welding becomes overheated. Explosion-proof tube axial fans ensure that the air in your space is safe to breathe, keeping dangerous fumes from accumulating and preserving the performance of crucial machinery. These fans provide protective conditions for workers, as well, by maintaining safe temperatures and reducing risks of fire.

Pharmaceutical and Food Processing

Some pharmaceutical and food processing facilities can come in contact with harmful dust or gas that sometimes will not appear to be dangerous but could explode. Explosion-proof tube axial fans are critical for keeping air clean and at an appropriate temperature to prevent potentially hazardous conditions.

Mining and Heavy-Duty Applications

There are also special ventilation problems in the mining atmosphere. Tube axial fans explosion-proof help maintain safe air quality in mining operations to avoid dust and gases from building up. These fans are designed to perform in the most extreme environmental conditions and the lowest of places.

The Advantages of Explosion-Proof Tube Axial Fans

Here are some of the most important benefits of using explosion-proof tube axial fans in hazardous applications:

- Enhanced Safety

The primary benefit of explosion-proof tube axial fans is that they can work within hazardous environments without being an ignition source. These blowers help in preventing explosions & fires through safe, effective ventilation. They are important for resisting mechanical or electrical sparks, which would otherwise cause anything explosive in the environment to ignite.

- Durability and Longevity

Explosion-proof tube axial fans are designed to last. Made from heat-resistant steel, cast aluminium and other durable materials, they can handle physical wear-and-tear, high temperatures and environmental stress. This long life translates to less replacement, downtime, and overall cost of maintenance for industries.

- Energy Efficiency

The fans’ axial-flow design enables them to achieve air flows of up to 8,000 m3/h without sacrificing energy efficiency. Explosion-proof tube axial fans keep operating expenses down with their low energy use and high-volume airflow.

- Compliance with Safety Regulations

These Fans are built to stringent safety standards ATEX and IECEx. They signify that the fans are safe for use in hazardous environments under international safety standards and give peace of mind to operators.

Conclusion

In applications where hot temperatures and dangerous surroundings are already the norm, explosion-proof tube axial fans are a necessity for safe, efficient, effective ventilation. In petrochemical plants, power stations, and heavy industry, these fans are used to control heat, suppress explosions, and protect people as well as machinery. In high-temperature industrial environments, explosion-proof tube axial fans are essential because they are durable, energy-efficient, and compliant with safety standards.

FAQ Schema:

- What are explosion-proof tube axial fans?

- Explosion-proof tube axial fans are specially designed fans used in environments with a high risk of explosion, such as chemical plants or power stations, to safely circulate air without causing ignition.

- Why are explosion-proof tube axial fans necessary in industrial plants?

- These fans prevent the risk of explosions by providing reliable air circulation in environments with flammable gases, dust, or volatile chemicals.

- How do explosion-proof tube axial fans work?

- These fans use an axial flow design, allowing them to efficiently move large volumes of air, while their explosion-proof enclosures ensure they don’t generate sparks that could ignite hazardous atmospheres.