In any industrial setting, the right materials can make a big difference. Electrical materials are especially important. The power machines, keep systems safe, and make sure everything runs smoothly. If the materials are weak or low quality, they can cause problems.

These include equipment failures, safety hazards, and even shutdowns. That’s why choosing durable electrical materials is key to keeping your industrial efficiency.

What Are Electrical Materials?

Electrical materials are the parts and products used to control, conduct, and protect electricity. They include:

- Wires and cables

- Switches and connectors

- Circuit breakers and panels

- Insulation and conduit

- Transformers and relays

These materials help build strong, reliable electrical systems. They are used in factories, warehouses, plants, and other industrial spaces.

The Importance of Durability

Durable materials last longer and perform better. They can handle harsh conditions, such as high temperatures, moisture, dust, and vibration. In an industrial setting, these conditions are common. That’s why it’s not just about choosing the cheapest option. It’s about choosing what will work best over time.

- Durable electrical materials:

- Reduce the need for repairs

- Lower maintenance costs

- Prevent accidents

- Improve safety

- Increase system reliability

Factors to Consider When Choosing Electrical Materials

Here are the top things to think about when selecting materials for your industrial project:

Material Quality

Choose products made from high-quality materials. Copper, for example, is a great conductor. It is used in many wires and cables because it conducts electricity well and lasts a long time. Aluminum is lighter and cheaper but less efficient.

For insulation, look for heat- and fire-resistant options. PVC and rubber are common choices that work well in different settings.

Voltage and Load Capacity

Each material has a rating for how much electricity it can handle. If you use materials that are too weak, they may overheat or fail. Always match your materials to your system’s voltage and current levels.

For example, power cables must be able to carry the load of the machines they serve. If not, they may melt or catch fire.

Environmental Conditions

Think about where the materials will be used. Will they be outside? Near water? In hot or cold temperatures?

For outdoor use, materials must resist UV rays, rain, and wind. In damp areas, waterproof insulation is important. For high-heat areas, thermal-resistant cables and parts are a must.

Safety Standards and Certifications

Check that the materials meet industry safety standards. Look for UL (Underwriters Laboratories), CE, or ISO certifications. These labels show that a product has passed tests for quality and safety.

Longevity and Maintenance

Choose materials that are easy to maintain and built to last. Some parts may cost more at first, but will save money in the long run because they don’t need frequent repairs. Look for materials with:

- Corrosion resistance

- UV protection

- Anti-flame properties

- These traits help the materials last longer and stay safe.

- Common Durable Electrical Materials

Here are some examples of electrical materials known for their strength and reliability:

Copper Wires

Copper is the most popular material for electrical wiring. It is strong, flexible, and conducts electricity very well. It can also resist corrosion, making it a long-lasting choice.

Armored Power Cables

Armored power cables have extra layers of protection. These include metal sheaths and insulation. They are perfect for harsh conditions and underground use.

These cables are often used in factories and plants where heavy machinery is involved.

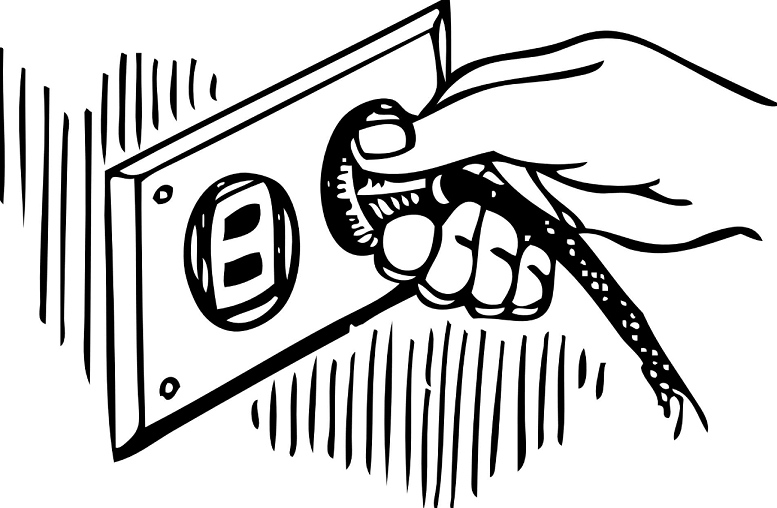

Industrial-Grade Switches and Sockets

Heavy-duty switches and sockets are built to handle high voltage. They have strong outer shells to protect them from impact and moisture.

Circuit Breakers with Thermal and Magnetic Trip Units

Circuit breakers with thermal and magnetic trip units provide dual protection to electrical systems. The thermal trip function automatically shuts off the power when the system overheats, preventing damage caused by excessive temperature.

Meanwhile, the magnetic trip responds swiftly to short circuits by cutting off the power almost instantly. This combination of thermal and magnetic protection enhances the overall safety and reliability of the electrical system.

High-Quality Insulation Materials

Good insulation keeps wires from touching each other or other objects. It prevents shocks, fires, and energy loss.

Rubber, PVC, and XLPE (cross-linked polyethylene) are strong choices for insulation.

Avoiding Common Mistakes

Even with the best intentions, mistakes can happen when selecting electrical materials. Here are some common ones to watch out for, along with tips to avoid them:

Using the Wrong Type of Material

Not all electrical materials are made for every job. For example, materials meant for indoor use may not withstand the elements when placed outside. Likewise, low-temperature-rated insulation might fail in high-heat environments.

Choosing Based on Price Only

It might be tempting to go with the cheapest option, especially for large projects. However, low-cost materials often come with lower durability, less protection, and shorter life spans. In the long run, using cheap materials can lead to higher maintenance costs, system failures, and even safety hazards.

Not Planning for Future Growth

Electrical systems often need to expand as a business grows. If you select materials that only meet your current needs, you might face problems during future upgrades.

This can lead to costly replacements or redesigns. It’s smarter to use cables, panels, and breakers that allow for extra load or easy integration with new systems later on.

Ignoring Installation Guidelines

Improper installation can ruin even the best electrical materials. Skipping instructions or using unqualified workers can result in loose connections, short circuits, or code violations. Always follow the manufacturer’s guidelines and hire certified professionals to install and inspect your electrical systems.

Skipping Regular Maintenance Checks

Once installed, electrical systems should be checked regularly. If you neglect inspections, small issues can grow into bigger problems. Worn-out insulation, loose fittings, or hidden corrosion can all reduce system efficiency and increase the risk of failure. Set up a schedule for routine checks and preventative maintenance.

By avoiding these common mistakes, you can create a safer, more efficient, and longer-lasting electrical system for your industrial setting.

Industrial Efficiency and Smart Choices Lead to Big Results

Choosing durable electrical materials is one of the smartest moves you can make for industrial efficiency. Strong, reliable materials keep your systems running safely and smoothly. They reduce downtime, improve safety, and save money over time.

Don’t cut corners when it comes to power cables, wires, switches, or breakers. Make smart, long-term choices that support your business now and in the future.

Liked this article? Check out more in this section for the latest updates!